In my last blog, I highlighted that many organisations are bogged down by increasing maintenance costs, often driven by deferred maintenance backlogs, highly reactive maintenance requirements, and business continuity risks.

In this blog, I’d like to share ways to elevate your maintenance strategy to combat these increasing costs. By aligning your work order prioritization with broader business objectives, you can accomplish many beneficial outcomes, including:

- Balancing Reactive vs Preventive Maintenance

Urgent fixes often overshadow planned work, with maintenance and field service managers frequently struggling to juggle emergency repairs and scheduled preventive tasks. In the railway sector, for example, unpredictable track or equipment failures demand immediate attention, forcing managers to constantly re-prioritize and alter planned maintenance schedules with the limited resources at hand. This overemphasis on fixing breakdowns after they occur leads to frequent disruptions and reduced overall productivity, resulting in poor customer experiences. - Reconciling a High Volume of Work Orders With a Limited Workforce

Having fewer technicians on hand means managers must pick and choose which work orders to tackle now and which to postpone, risking longer downtime for non-critical assets. Hospitals must work within tight budgets with limited resources and constant regulatory monitoring to maintain safe, compliant environments for patients. When maintenance managers face staffing shortages, they have to defer lower-priority tasks and find ways to reduce costs without compromising patient care.

Similarly, field service managers are forced to constantly prioritize which tickets get a technician today, and which ones wait until tomorrow or next week, simply due to manpower limits. Urgent incidents, such as a power outage or a downed cell tower, will pull technicians away from less critical jobs, creating a cascading reprioritization of all other open work orders. Skilled labour shortages in this industry and others only exacerbate the issue, with a recent industry analysis finding that the global skilled labour gap could leave 85 million jobs unfilled by 2030, hitting technical fields hard. - Overcoming Maintenance Backlogs

When everything feels like a priority, backlogs grow quickly. If emergency and urgent tickets continuously take precedence, preventive and routine tasks get delayed, creating a growing list of overdue work orders. Businesses can get trapped in a cycle where less-visible issues (like minor preventative fixes) are perpetually pushed back, compounding into large backlogs that undermine facility or equipment reliability, or even worse lead to larger, more costly issues. Eventually, this backlog itself becomes a challenge – deciding which of the many delayed tasks to do first can be overwhelming. Without clear prioritization criteria or tools, maintenance and field services managers find it difficult to break out of reactive mode. - Managing Stakeholder Communication and Expectations

When stakeholders are left in the dark about why a work order hasn’t been addressed yet, they may escalate the pressure, adding to the maintenance manager’s stress levels. Field service organisations have to prioritize not just based on technical needs but also customer impact, sometimes soothing an important client by expediting a request. Overall, living up to promised response times and keeping customers satisfied is a top-of-mind challenge that heavily influences how work orders are prioritized in day-to-day operations. - Ensuring Regulatory and Safety Compliance

For all the juggling that facility managers and field service personnel are asked to do, some mandatory tasks cannot be deprioritized. Many facility managers, particularly in heavily regulated industries, face non-negotiable work orders related to safety and compliance. These include scheduled inspections, safety system tests, and legally mandated maintenance that must occur by set deadlines. The challenge arises when simultaneous demands occur, such as an emergency breakdown versus a due compliance task. Ensuring nothing slips through is a heavy burden that elevates the complexity of managing work order priorities. - Meeting SLAs and Response-Time Expectations

Facility and field services managers face a great deal of pressure to resolve critical issues quickly. This challenge intensifies when multiple high-priority incidents occur simultaneously. It then becomes nearly impossible to meet every time commitment, forcing providers to triage and possibly violate some SLA windows. Failing to meet these targets can result in penalties, lost business, or harm to the client’s operations.

How to start?

If businesses are looking to implement effective maintenance work order prioritization, the first step is to identify objectives and observation topics. Topics allow organizations to categorize and search collected Observations (risks and opportunities) that are registered by various stakeholders for assets, spaces and properties. Topics may include activities related to equipment performance, compliance, maintenance, safety, or sustainability.

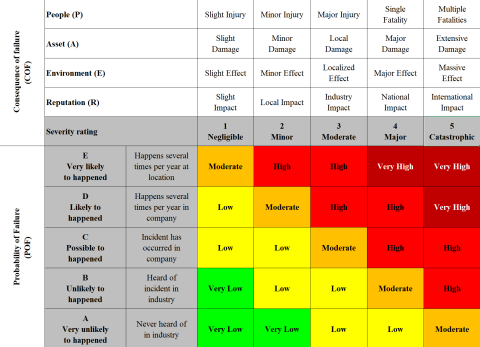

Facility managers and field services providers can define a scoring method for each topic to help identify where the risks and opportunities are and to prioritize any automatic follow-up actions. An example of a scoring method is a risk matrix.

Customers can define their own matrix to determine work order prioritization and create decision models, making them as simple or as detailed as required to meet organisational objectives.

Follow-up activities may be assigned to internal or subcontractor resources based on various criteria, such as risk level, work type, trade, location, technician availability, required certifications and skills. It’s then up to organisations to implement and monitor the follow-up actions. Service contracts are automatically monitored with alerts on SLAs, cost and quality. This allows organisations to improve their resourcing strategy and reduce associated costs.

Elevate Your Work Order Management with Objective-Based Maintenance

As an industry-leading maintenance and field service management software provider, Planon understands the importance of work order prioritization. Our unified platform for centralised work order management, scheduling, and dispatch enables facility managers and field services planners to master the art of work order prioritization with an objective-based maintenance strategy.

Our hyper-automated workflows supercharge efficiency, eliminate bottlenecks and deliver compliance, employee wellbeing and customer satisfaction. Leverage real-time updates so field technicians have the right insights and information to perform service activities with confidence and accuracy. Plus, our detailed reporting lets you track progress, prove successes, and strengthen customer trust and loyalty.

Do you want to learn more about work order prioritization with Planon? Contact us for a demo about improving your maintenance strategy today!